When it comes to selecting the right material for industrial, construction, or manufacturing projects, the debate between aluminium plate and steel plate often arises. While both are widely used metals, they possess distinct properties that make them suitable for different applications. In this article, Aluminium Plate vs. Steel Plate: Key Differences Explained, we will break down their unique characteristics, uses, and how to choose the right one for your needs.

1. Composition and Weight

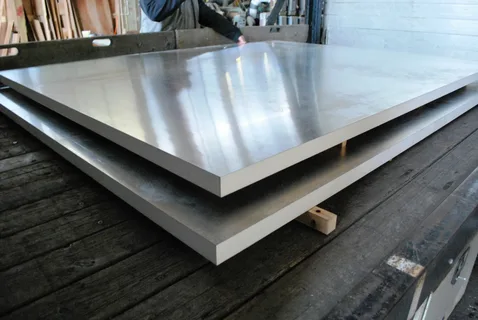

Aluminium Plate

Aluminium is a lightweight metal known for its low density. An aluminium plate is typically around one-third the weight of a steel plate of the same dimensions. This makes it ideal for applications where weight is a concern, such as in the aerospace and automotive industries.

Steel Plate

Steel is significantly denser and heavier. It contains iron and carbon, and depending on the alloy, it can also include other elements. The added weight of steel provides strength and stability, making it ideal for structural applications.

2. Strength and Durability

Steel Plate Advantages

Steel plates are renowned for their strength, hardness, and ability to withstand heavy loads and harsh conditions. They are preferred in construction, shipbuilding, and heavy equipment manufacturing due to their high tensile strength.

Aluminium Plate Performance

Although aluminium is not as strong as steel, it has excellent resistance to corrosion and is more malleable. Modern aluminium alloys can also offer impressive strength, but steel still leads in durability for extreme load-bearing applications.

3. Corrosion Resistance

Aluminium naturally forms a protective oxide layer that shields it from corrosion, making it an excellent choice for marine and outdoor applications without the need for coatings or treatments.

Steel, especially carbon steel, is prone to rust if not properly coated or galvanized. However, stainless steel variants offer improved corrosion resistance at a higher cost.

4. Cost and Availability

Aluminium Plate

Generally, aluminium is more expensive than steel on a per-pound basis. The refining and processing costs contribute to this difference. However, its lightweight nature can lead to cost savings in transportation and handling.

Steel Plate

Steel is more affordable and readily available in a wider variety of grades and thicknesses. For projects requiring large quantities of material, steel plates are often the more economical choice.

5. Applications: When to Choose What

Understanding your specific application is crucial in the aluminium plate vs. steel plate decision.

- Choose aluminium plate if you need a lightweight, corrosion-resistant material for transportation, aerospace, or marine environments.

- Choose steel plate for high-strength requirements such as bridges, buildings, and heavy-duty machinery.

Conclusion

In summary, Aluminium Plate vs. Steel Plate: Key Differences Explained helps us see that while both materials are indispensable in industry, each serves different purposes based on their properties. Aluminium offers lightweight corrosion resistance, while steel provides unmatched strength and cost-effectiveness. The right choice depends on your project’s specific demands.

Before making a final decision, always consider the working environment, budget, weight restrictions, and required durability to ensure the material you choose is fit for purpose.